Solar power generation is a technology that converts sunlight into electricity, utilizing solar panels to directly transform light energy into electrical energy. This technology not only helps increase energy self-sufficiency but also boasts low environmental impact due to no noise, vibration, exhaust gases, or wastewater. By reducing greenhouse gas emissions, it contributes to combating climate change. Throughout the lifecycle of a photovoltaic (PV) power station, cables act as the system's "blood vessels." Their reliability directly impacts power generation efficiency and operational safety.

KIBOR Cable has deep expertise in the new energy sector. Based on a profound understanding of PV application scenarios, we offer a comprehensive series of professional PV cable solutions.

Injecting the Gene of Stable Operation into PV Power Stations

——KIBOR's Complete PV Cable System Solution

Product Advantages:

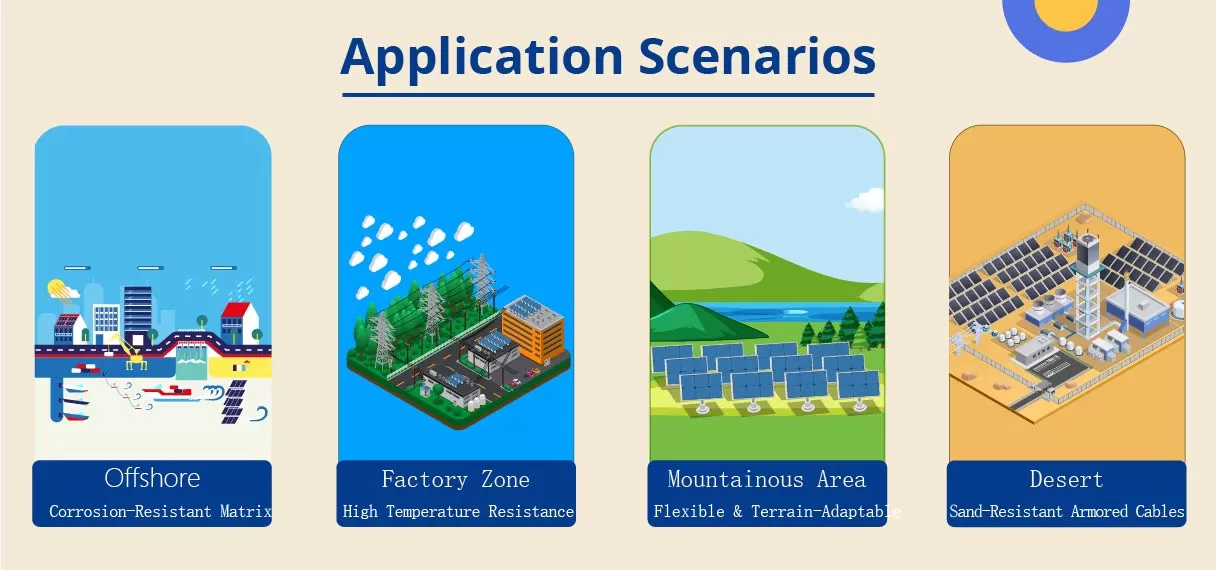

• Outstanding Weather Resistance: Special insulation materials and jacket formulations offer UV resistance, high/low temperature tolerance (-40°C to 90°C), adapting to harsh environments like deserts, coastlines, and high altitudes.

• Long-Term Stable Operation: Tinned copper core conductors ensure conductive stability, minimizing system losses to the greatest extent.

• Comprehensive Safety Assurance: Flame-retardant, anti-corrosion, and ozone-resistant design, certified by TÜV, UL, CQC, and other international standards.

Innovative Solutions:

• Armored Protective Cables: Utilize metal armor structure for excellent mechanical protection, effectively resisting external damage such as rodent bites and rock compression. Particularly suitable for direct burial and harsh environments.

• High-Voltage Transmission Solutions: Cater to large-scale power station needs with high-voltage cable products, improving transmission efficiency and reducing system costs.

• Full-Scenario Adaptation: Provide a complete product series from module connection, combiner box transmission to grid connection, meeting the requirements of various PV projects.

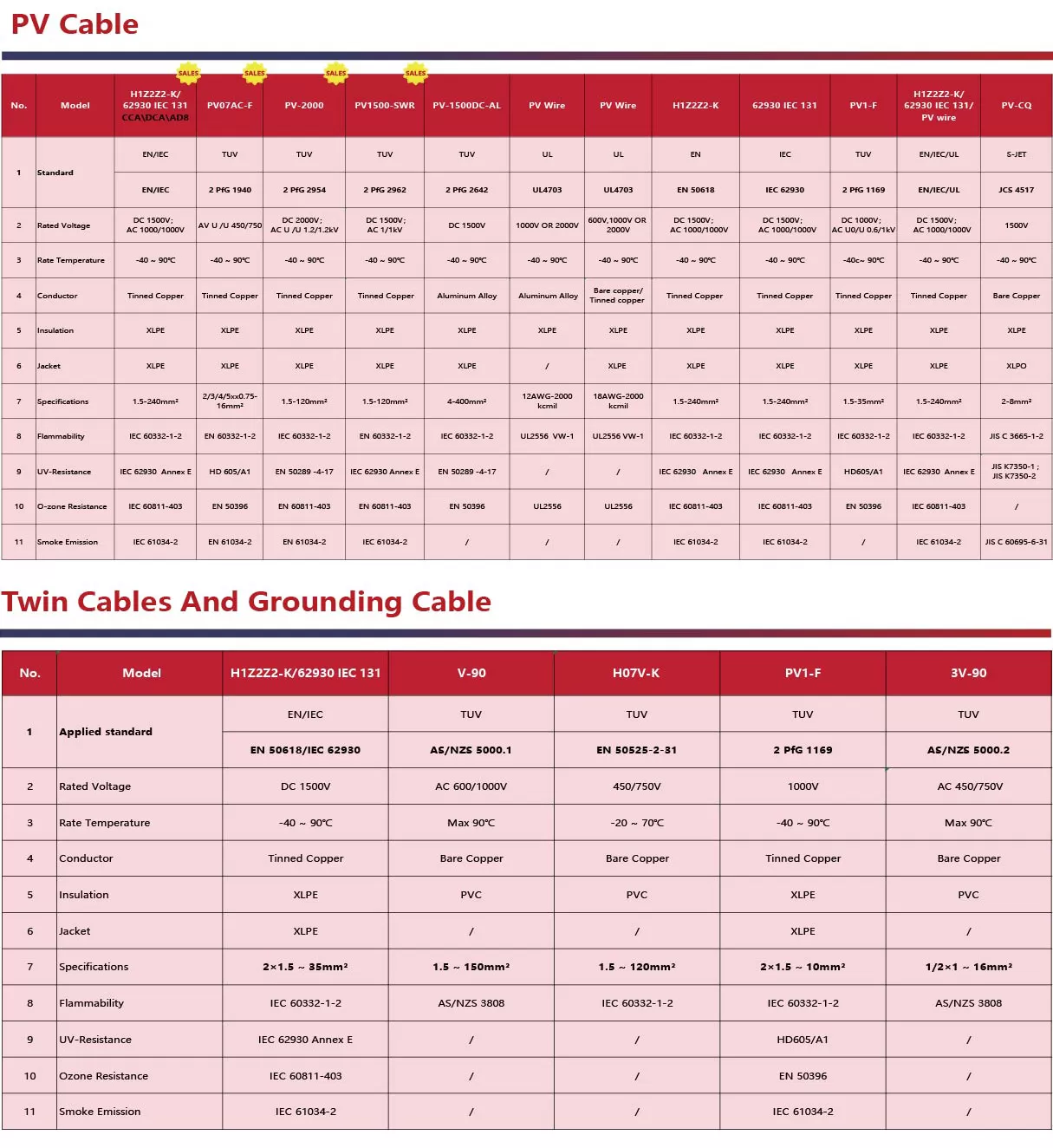

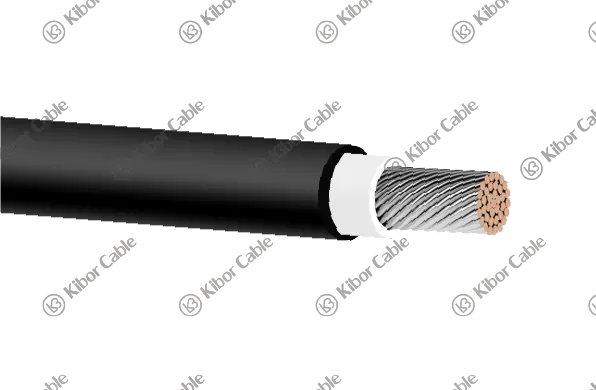

H1Z2Z2-K is a DC cable specially designed for PV power generation systems. This product uses halogen-free cross-linked polyolefin material, boasting excellent weather resistance capable of long-term resistance to UV, ozone, and various harsh climatic conditions. The cable features a wide operating temperature range and outstanding flame-retardant performance, with a design perfectly matching the lifecycle of PV systems. The product is certified by international standards like TÜV and can be widely used for connections between solar panels and DC-side wiring in PV power stations. It is an ideal choice for the safe and reliable operation of PV power generation systems.

H07V-K is a single-core PVC insulated cable compliant with European standards (HAR). This cable uses fine-stranded bare copper conductors and PVC insulation material, offering good electrical performance and mechanical protection. Its rated voltage is 450/750V, suitable for fixed installations, with an operating temperature range of -20°C to +70°C. Widely used for internal equipment wiring, control systems, and fixed electrical installations, it is an ideal choice for industrial equipment and control cabinet wiring.

UL PV Cables are dedicated cables compliant with US safety standards UL4703 and UL44. They utilize weather-resistant cross-linked polyolefin material with features like UV resistance and flame retardancy, specifically designed for DC-side power transmission in solar PV systems, ensuring long-term stable operation in harsh outdoor environments.

For DC-side connections, we provide dedicated tools such as connectors and extension harnesses. These components feature waterproof and UV-resistant designs, ensuring stable performance in harsh outdoor environments. Our connection solutions support quick plug-and-play and tool-free installation. Combined with pre-assembled waterproof harnesses, they can significantly improve on-site construction efficiency. They are also equipped with professional crimping tools and testing equipment to ensure the reliability of each connection point and system safety.