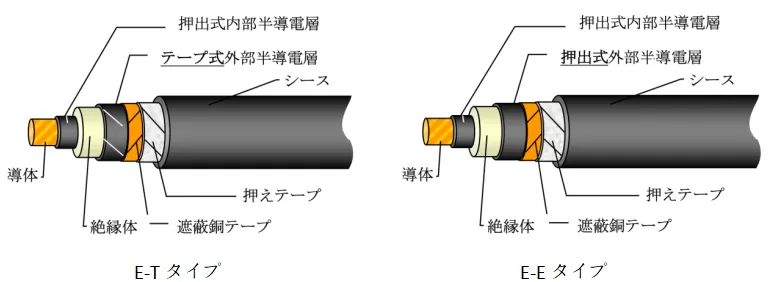

What are the differences between the E-T/E-E types of high-voltage CV cables?

High-voltage CV cables mainly come in two specifications: E-T type and E-E type. The difference between the two particularly lies in the manufacturing method and structure of the external semiconductive layer.

Model introduction of E-T and E-E:

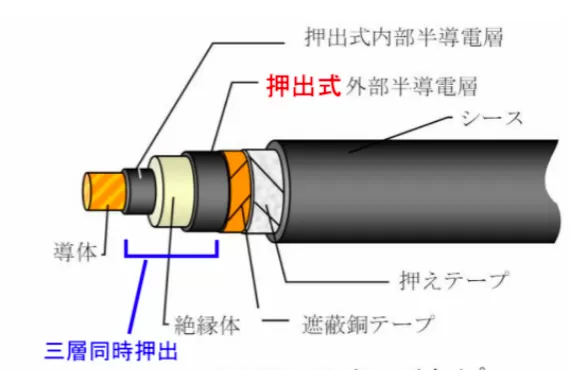

The E-E type is formed by simultaneously extruding three layers: the internal semiconductive layer, the insulator, and the external semiconductive layer. This kind of" "Three-layer simultaneous extrusion";" The process enables the interfaces of each layer to form continuously and smoothly at the molecular level, preventing the mixture of foreign substances and the formation of voids. Its characteristics are extremely excellent water resistance and high long-term reliability. JEAC 8011 (Code for High Voltage Receiving Equipment) also recommends the E-E type from the perspectives of water resistance and safety.

The E-T type is a method where the internal semiconductive layer and insulator are extruded into shape and then wrapped with semiconductive tape as the external semiconductive layer. Due to the fact that the interface of the tape is prone to generating fine steps and gaps, there is a risk of water intrusion and partial discharge. Therefore, compared with the E-E type, its water tightness resistance is poorer. On the other hand, it has the advantage of relatively easy terminal handling during construction and is widely used for general users, etc.

Types | Internal semiconductive layer | 外部半导电层 | 主要特点 |

E-T | Extrusion formula (E) | Magnetic tape type(T) | Wrap external semiconductive tape around the insulator. The terminal processing is convenient. |

E-E | Extrusion formula (E) | Extrusion formula (E) | Three layers of を are extruded simultaneously. The interface is が integrated が and has excellent water resistance トリ and に performance れる. |

Application standards for E-T and E-E types:

E-E type: Recommended for use in power companies, railway companies and other places where system reliability is particularly emphasized, as well as in environments with high risks of water damage such as flooding and constant humidity.

E-T type: It is suitable for general buildings, commercial facilities, factories and other occasions that pursue a balance between cost performance and constructability. It also has a rich track record in high-voltage cables and fully demonstrates its performance under standard conditions.

The T-type (E-T) has many practical achievements among general users and has sufficient performance as a high-voltage cable. Compared with the T-type, the E-E type has better waterproof performance, especially when used in harsh environments where cables are frequently immersed in water.

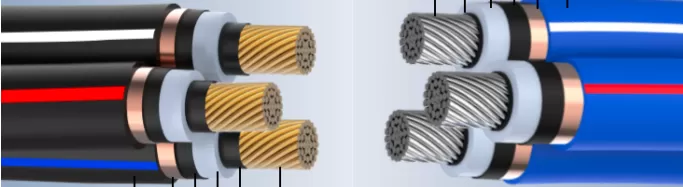

KIBOR high-voltage cable types

KIBOR CABLE adopts the E-E type (three-layer simultaneous extrusion type) in high-voltage CV cables that require high reliability and long service life.

KIBOR's E-E type high-voltage cable adopts a three-layer integrated extrusion molding method of internal semiconductive layer, insulator and external semiconductive layer, which significantly enhances the adhesion at the interface, inhibits the intrusion of moisture and partial discharge. Therefore, it can demonstrate excellent durability even in harsh conditions such as damp environments and underground installations

。

On the picture of copper and the signal transmitter, refer to the method shown in the following figure. Together with the copper signal transmitter, frame out the inner semiconductive layer, insulating layer, and outer semiconductive layer, and mark ";" "Three-layer simultaneous extrusion";" . Then click on this picture to connect to ";" Product Introduction The following" High-voltage copper cable (Back of the page) Then click on this image to display it as the main image of this article.

KIBOR E-E type high-voltage CV (copper) cable KIBOR E-E type high-voltage AL-CV (aluminum) cable

It not only complies with the strict specifications of the power company, but also conforms to the technical standards recommended by JEAC 8011 (Code for High-Voltage Receiving Equipment), achieving consistent high reliability and safety from the initial stage of the equipment to long-term operation. KIBOR's E-E high-voltage cables contribute to the stable operation of power infrastructure and implement a high level of quality management from design to manufacturing.